In the world of industrial and construction projects, efficiency and precision are paramount. Any delays, miscalculations, or installation issues can escalate costs, extend timelines, and compromise safety. Pre-fabricated piping spools have emerged as a solution to these challenges, offering a streamlined, quality-controlled approach that enables faster and more efficient project execution. This post delves into the benefits of pre-fabricated piping spools, explaining why they have become a preferred choice for engineers, contractors, and project managers looking to enhance productivity and minimize project risks.

What Are Pre-Fabricated Piping Spools?

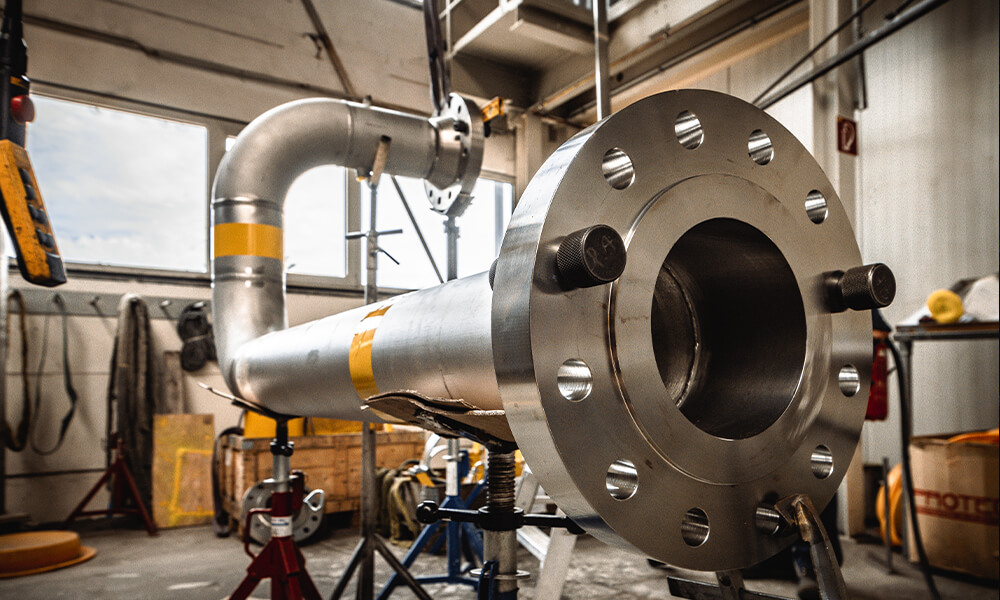

Pre-fabricated piping spools are segments of piping that are manufactured off-site in a controlled environment according to specific project designs. Each spool typically consists of pipes, flanges, fittings, and other necessary components welded or assembled in alignment with the final system’s design. Once the fabrication process is complete, these spools are transported to the project site for quick installation.

This pre-fabrication approach offers substantial benefits by cutting down on-site assembly, reducing the need for skilled labor, and minimizing disruptions during the final installation process.

Key Benefits of Pre-Fabricated Piping Spools for Project Efficiency

Reduced On-Site Work and Faster Installation

Pre-fabrication significantly reduces the amount of work required at the project site. Since the piping spools are manufactured off-site, they arrive at the location ready for installation. This not only saves time but also ensures greater accuracy, as the spools are created to exact specifications in a controlled environment with minimal risk of errors.

Less on-site work translates to faster installation times, which is particularly beneficial in projects with tight deadlines or where minimizing operational downtime is essential.

Enhanced Quality Control

When piping components are fabricated on-site, the chances of error increase due to environmental and logistical challenges. Pre-fabricated spools, however, are manufactured in a controlled environment under strict quality control measures. The process allows for precision welding, exact measurements, and adherence to quality standards that may be difficult to maintain in on-site conditions.

This attention to detail ensures that each spool meets high standards, ultimately reducing the likelihood of issues arising during or after installation. Moreover, pre-fabricated spools undergo rigorous testing, including dimensional and hydrostatic testing, ensuring that they meet project specifications and industry regulations.

Cost Savings Through Efficiency

Pre-fabricated piping spools provide several avenues for cost savings:

- Reduced Labor Costs: Off-site fabrication minimizes the need for skilled labor at the installation site, as less manual work is required to assemble the system.

- Less Material Waste: Precise fabrication reduces material wastage, which can be significant when cutting, welding, and fitting are done on-site.

- Reduced Equipment Rental Time: Faster installation reduces the time spent renting heavy machinery and other equipment on-site, resulting in lower project costs.

By streamlining the installation process and reducing waste, pre-fabricated piping spools offer a cost-effective solution that can keep project budgets in check.

Increased Safety and Reduced On-Site Hazards

One of the main concerns during on-site assembly is worker safety, especially in large projects with high volumes of heavy machinery and equipment. Pre-fabrication moves much of the assembly work off-site, reducing the need for on-site cutting, welding, and other high-risk activities.

As a result, the on-site environment becomes less congested, and the risk of accidents due to hazardous conditions is minimized. Safety is further enhanced by reduced exposure to extreme weather conditions, toxic materials, or confined spaces that often characterize on-site work.

Minimized Project Delays Due to Environmental Factors

Weather and environmental conditions can be unpredictable, causing delays in on-site construction. Rain, extreme temperatures, and high humidity can interfere with processes like welding and painting, extending the timeline for piping installations.

Pre-fabricated spools are manufactured indoors, where environmental factors have no impact on production timelines. By handling most of the fabrication off-site, pre-fabrication helps to keep projects on track, avoiding costly delays and meeting project deadlines regardless of on-site weather conditions.

Customization and Flexibility

Pre-fabricated piping spools offer high customization potential, as each spool can be designed and built to meet specific project needs. This flexibility is invaluable for complex projects, such as those in the oil and gas, petrochemical, and power industries, where precise specifications and unique layouts are often required.

By designing and assembling spools tailored to project requirements, contractors can avoid costly modifications or rework that may be necessary with standard on-site fittings.

Improved Project Planning and Management

With pre-fabricated spools, project managers can have a clearer timeline and better control over project stages. By coordinating spool fabrication and site preparation in parallel, teams can save time, ensuring that site work and fabrication work are completed simultaneously.

The controlled process and clear project timeline provided by pre-fabrication also enable easier tracking of project milestones and more accurate cost estimation, making resource allocation and overall management more efficient.

Applications of Pre-Fabricated Piping Spools

Pre-fabricated piping spools are used across a range of industries, including:

- Oil and Gas: Often used for piping systems in refineries, petrochemical plants, and offshore platforms.

- Power Generation: Essential for high-pressure piping in thermal power and nuclear power plants.

- Chemical and Pharmaceutical: Used for safe and precise transport of chemical substances in processing plants.

- Water Treatment and Waste Management: Suitable for water and sewage treatment plants, where efficiency and safety are essential.

These applications highlight the versatility of pre-fabricated spools in supporting complex systems across diverse industrial needs.

Final Thoughts

In an industry where project efficiency, safety, and quality are critical, pre-fabricated fittings offer a practical and effective solution. By streamlining installation, enhancing quality control, and reducing on-site labor requirements, pre-fabricated spools contribute to quicker, safer, and more cost-effective project execution. For companies looking to optimize their projects, investing in pre-fabricated piping spools can make a substantial difference in project outcomes, paving the way for a more reliable and sustainable future in industrial construction.

Choosing pre-fabricated piping spools could be the key to achieving project success, and as the technology advances, their role in modern construction will only continue to grow.

How Often Should a Roof Be Replaced?

How Often Should a Roof Be Replaced?  Narra Residences Unveil Supreme Elegance in Singapore’s Dairy Farm Walk

Narra Residences Unveil Supreme Elegance in Singapore’s Dairy Farm Walk  Emergency Roof Repair in Wyoming: What to Do When Disaster Strikes

Emergency Roof Repair in Wyoming: What to Do When Disaster Strikes  Red Flags to Watch Out for When Choosing a Real Estate Agent

Red Flags to Watch Out for When Choosing a Real Estate Agent  How Site Preparation Impacts the Success of Concrete Construction

How Site Preparation Impacts the Success of Concrete Construction  Florida’s Venomous Spiders: What to Know and When to Worry

Florida’s Venomous Spiders: What to Know and When to Worry  Why Homeowners Trust Sewer Camera Inspections for Accuracy

Why Homeowners Trust Sewer Camera Inspections for Accuracy  Modern Tempered Glass Doors Enhance Interiors With Sleek Functionality And Aesthetic Value

Modern Tempered Glass Doors Enhance Interiors With Sleek Functionality And Aesthetic Value  Earning the CCIM Designation: Required Education, Experience, and Industry Commitments

Earning the CCIM Designation: Required Education, Experience, and Industry Commitments